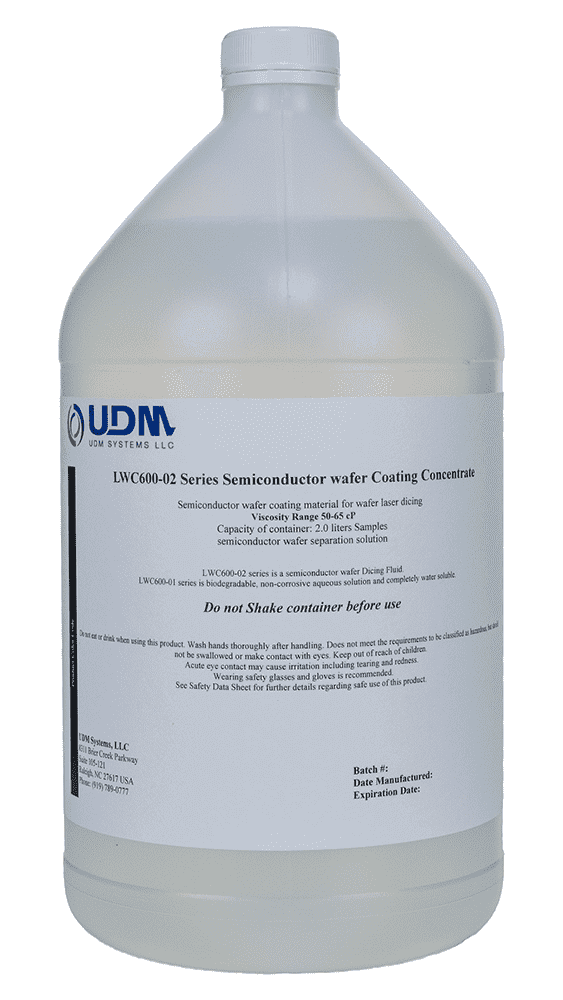

LWC600 Series Wafer Coating Material for Laser Dicing Application

LWC600 is designed to protect wafer surfaces while laser dicing/cutting semiconductor wafers. It has a unique feature that effectively prevents debris and residue from adhering/sticking to the wafer surface during wafer laser dicing process.

Use UDM FLC200 in the scrubbing station to clean and remove any residue or contaminants remaining on wafer surfaces.- The unique feature effectively prevents debris and residue from adhering/sticking to the wafer surface during wafer laser grooving/dicing process.

- Effectively protects the wafer/substrate during proving process from slag contaminants.

- 100 % soluble in DI water in all proportion. LWC600-02 is completely rinsed off with DI water.

- LWC 600-02 aids in heat dissipation and reduces the power of the laser.

- Viscosity 50-150 cP (centipoise) or mPa.s (millipascal seconds).